Contents

At a time when sustainability isn’t just a trend, it’s a necessity, finding packaging solutions that are both environmentally responsible and high-performance is critical. Enter the world of recycled pulp cartons, where innovative design meets eco-friendly practices. This guide takes an in-depth look at the six leading recycled pulp egg cartons on the market, ultimately presenting the most versatile, durable, and environmentally friendly products. Whether you’re a manufacturer, distributor, or retailer, this comprehensive guide will give you the knowledge you need to make smart decisions about your packaging needs.

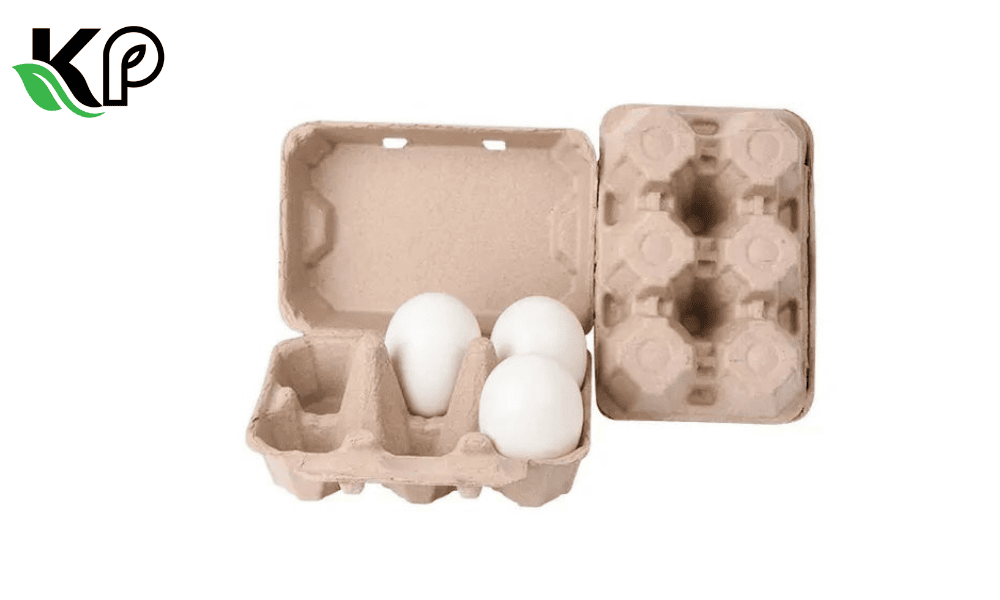

Recycled pulp cartons revolutionize packaging by transforming post-consumer paper waste into robust, form-fitting containers. Unlike traditional foam or plastic trays, recycled pulp harnesses the inherent strength of cellulose fibers, delivering shock absorption and structural integrity that protect fragile goods. Our Egg Box cartons are crafted from 100% reclaimed fibers, processed under stringent quality controls to ensure uniformity.

The manufacturing process begins with sorting and pulping, where water and mechanical agitation separate fibers from ink and contaminants. Advanced screening and cleaning steps remove residual impurities, yielding a homogenous slurry. This slurry is then molded into the familiar honeycomb structure that cradles each egg in its own compartment, preventing collisions and breakage—even under stacking weight.

Key innovations in our Egg Box line include:

Optimized fiber blend: Combining long and short pulp fibers for superior tensile strength and cushioning.

Water-efficient molding: Utilizing closed-loop water systems to minimize consumption.

Low-energy drying: Employing infrared and gentle air flow to reduce carbon footprint.

By focusing on closed-loop manufacturing and renewable energy sources, recycled pulp cartons deliver a significant reduction in greenhouse gas emissions compared to virgin-material alternatives. This sustainable material innovation not only meets current eco-regulations but sets a benchmark for future packaging solutions.

Egg Box supplier

At the heart of every standout packaging solution are features that address real-world challenges. Our Egg Box cartons boast a suite of advantages tailored to egg producers and packers seeking reliability and sustainability.

Shock Absorption and Structural Rigidity

The proprietary molding process creates a micro-cellular structure that disperses impact forces, drastically reducing breakage during transit. Unlike flimsy cardboard trays, these cartons maintain shape integrity under heavy stacking loads, ensuring eggs arrive intact from farm to shelf.

Moisture Resistance and Breathability

While recycled pulp is inherently hydrophilic, a light, food-safe coating renders the carton moisture-resistant without compromising breathability. This balance helps maintain the ideal humidity around eggs, preventing condensation and extending shelf life.

Thermal Insulation

The air pockets within the fiber matrix act as natural insulators, buffering eggs against temperature fluctuations during transport. This passive thermal protection is especially valuable in cold-chain logistics where power outages or delays can compromise product quality.

Custom Fit and Versatility

Our Egg Box series comes in a variety of compartment counts—from six-packs to thirty-two compartments—each precisely engineered to cradle standard and specialty egg sizes, including poultry and quail. Custom die-cuts accommodate organic, free-range, and specialty eggs, ensuring a snug fit without extra void fill.

Stacking Efficiency and Nesting

Innovative interlocking flanges allow cartons to nest securely, maximizing pallet density and reducing shipping volumes. This means fewer trucks on the road, lower fuel consumption, and decreased overall logistics costs.

Taken together, these functional advantages position recycled pulp cartons as the premier choice for anyone serious about product protection, sustainability, and cost efficiency.

Though designed with eggs in mind, recycled pulp cartons find applications well beyond egg packaging. The versatility of fiber-based molding lends itself to myriad fragile products:

Fresh Produce: Delicate fruits such as figs, berries, and cherry tomatoes benefit from the same cushioning properties that safeguard eggs.

Electronics: Small electronic components and circuit boards require anti-static and shock-absorbing trays, which can be achieved with modified pulp blends.

Cosmetics: Glass bottles and jars for high-end skincare products are shielded against breakage, elevating the unboxing experience.

Pharmaceutical Vials: Temperature-controlled pulp carriers protect vials in transit, maintaining integrity for critical medications.

Industrial Parts: Precision metal or plastic parts for automotive and aerospace industries rest securely in custom molded cavities.

In each of these sectors, the Egg Box ethos—combining form-fitting design, environmental stewardship, and cost-effectiveness—delivers tangible benefits. Companies that adopt recycled pulp solutions not only reduce single-use plastic dependence but also resonate with eco-conscious consumers, strengthening brand reputation.

The shift from petroleum-based packaging to recycled pulp is a cornerstone of the circular economy. By repurposing paper waste, we extend the life cycle of fiber resources and limit landfill accumulation.

Carbon Footprint Reduction

Recycled pulp cartons demand less energy in fiber refinement than virgin paperboard production. Our in-house life-cycle assessment shows a 40% reduction in CO₂ emissions per ton of pulp processed, thanks to energy-efficient machinery and renewable energy sourcing.

Water Conservation

Closed-loop water systems recapture and treat process water, cutting freshwater intake by up to 60%. This is critical in regions facing water scarcity, where packaging manufacturers must be responsible stewards of local resources.

Biodegradability and Compostability

Unlike expanded polystyrene (EPS) and certain plastics, recycled pulp cartons are fully biodegradable and industrially compostable. When disposed of properly, they break down into harmless humus, returning nutrients to the soil. This organic end-of-life outcome closes the loop, ensuring minimal environmental impact.

Waste Diversion and Recovery

Post-consumer collection programs recover used cartons, channeling them back into pulp mills. Each recycling loop conserves raw material and further reduces energy inputs. Our Egg Box cartons are designed for easy pulping, with coatings and additives selected for compatibility with standard recycling streams.

Embracing recycled pulp packaging is more than a marketing story; it’s an actionable strategy for sustainability, resource conservation, and compliance with evolving environmental regulations worldwide.

When evaluating packaging alternatives, stakeholders must weigh cost, performance, and environmental footprint. Here’s how recycled pulp cartons stack up against common contenders:

Compared with Expanded Polystyrene (EPS)

Shock Protection: Comparable cushioning, but EPS lacks biodegradability.

Environmental Impact: EPS persists for centuries, while pulp breaks down in months.

Cost: EPS may be marginally cheaper, but end-of-life disposal fees and regulatory pressures erode savings.

Compared with Molded Pulp (Non-Recycled Virgin Fibers)

Resource Use: Pure pulp uses virgin trees, whereas recycled pulp leverages post-consumer waste.

Carbon Emissions: Virgin pulp requires more energy to strip lignin and bleach fibers.

Performance: Functionally similar, but recycled pulp scores higher on sustainability metrics.

Compared with Cardboard Trays

Strength: Molded pulp offers 3× the compression resistance of simple cardboard die-cuts.

Customization: Cardboard is limited in intricate cavities; pulp molding allows precise geometries.

Market Perception: Consumers often view cardboard as “cheap,” whereas molded pulp communicates quality and care.

By selecting our Egg Box solution, businesses secure high-performance packaging that meets or exceeds the protective qualities of plastics and virgin-fiber products, while championing sustainability. This holistic advantage drives cost savings in logistics, waste management, and brand loyalty.

In today’s competitive retail landscape, packaging is more than a container—it’s a brand ambassador. Our Egg Box line offers extensive customization options to reinforce brand identity and consumer engagement.

Color and Finish

Although primarily offered in natural gray and tan hues, we can apply food-safe water-based coatings in custom colors. Subtle textures or matte finishes elevate the tactile experience, inviting consumers to feel the quality before reading the label.

Embossing and Debossing

Raise or press your logo, product name, or QR codes directly into the pulp surface. This premium treatment adds a tactile dimension that resonates with upscale markets and conveys authenticity.

Direct Printing

Utilizing soy-based inks, we can print high-resolution graphics, product information, and branding directly onto the carton. This eliminates adhesives and labels, reducing material complexity and simplifying recycling.

Unique Shapes and Inserts

Move beyond standard grids. Custom molds create inserts for mixed product assortments (e.g., eggs paired with condiments or novelty items). Innovative shapes differentiate your brand on crowded shelves.

Smart Packaging Integration

Embed scannable NFC or RFID tags during molding, enabling real-time tracking, tamper evidence, and consumer engagement through mobile apps. This fusion of sustainable packaging and digital connectivity positions your brand at the forefront of innovation.

By leveraging these customization avenues, your Egg Box packaging becomes an extension of your marketing strategy, driving shelf impact and fostering brand loyalty.

Performance and safety go hand-in-hand. Our rigorous quality control protocols ensure each pallet of Egg Box cartons meets industry standards and regulatory requirements.

Food Safety Certifications

We comply with FDA 21 CFR 176.170 for indirect food contact, using pulp sourced from food-grade papers and inks approved for food packaging. Quarterly audits by third-party labs verify migration limits and microbial integrity.

ISO 9001:2015 Quality Management

Our production facilities operate under certified quality management systems, tracking everything from raw material inspection to final product testing. Traceability protocols document every batch, enabling swift corrective actions if deviations occur.

ASTM D6413 Flammability Testing

Carton materials undergo vertical flame testing to ensure compliance with transportation and retail fire safety codes. Our formulations achieve self-extinguishing ratings, limiting flame spread in worst-case scenarios.

International Standards

For export markets, we adhere to EU Regulation 10/2011 on plastic materials in contact with food (applicable to coatings and inks), as well as ISO 14001 environmental management benchmarks. This global compliance streamlines cross-border distribution for producers serving multinational clients.

By prioritizing regulatory alignment and continuous improvement, Egg Box cartons deliver consistent, reliable performance that stands up to rigorous scrutiny—protecting both your products and your brand reputation.

wholesale Egg Box

Crafting a packaging solution that balances performance, sustainability, and cost-effectiveness is no small feat. Our high quality Egg Box cartons rise to this challenge, offering advanced fiber technology, end-of-life eco-credentials, and customizable branding capabilities. Whether you’re safeguarding delicate farm-fresh eggs, premium cosmetics, or precision components, recycled pulp packaging sets the standard for responsible innovation.

Engage with our expert team today to explore how Egg Box solutions can transform your packaging strategy—driving operational efficiencies, bolstering brand value, and championing a greener future for us all.For example: “Want to learn more about Egg Box purchasing? Contact us now to get a quote!”

Previous News

Save 500+ Plastic Cups a Year with Recycled pul...Next News

Ditch Plastic! Switch to Recycled Pulp Cup Hold...

The KP-BN02 Cup Holder is an excellent choice ...

The KP-KD1 Cup Holder is designed to provide a ...

The KP-MD4 Cup Holder is designed to provide a ...