In early 2025, federal policy discussions have centered on safety and quality in the food service industry, including Cup Holder. New regulations aim to enhance material safety, reduce environmental impact, and ensure product quality. These updates encourage innovation in design while promoting sustainable practices.

Contents

Across bustling cafés in Kuala Lumpur, drive‑throughs in Sydney, and pop‑up espresso bars in New York, the humble Cup Holder sits quietly between brewer and consumer—insulating hands, preventing spills, and keeping multiple beverages upright on the journey from counter to curbside. Yet this modest accessory is now centre stage in global sustainability debates.

Governments from the European Union to ASEAN have declared an end to business‑as‑usual, replacing foam and virgin‑plastic carriers with renewable, compost‑friendly alternatives. Recycled paper pulp is emerging as the star solution, marrying convenience with measurable environmental gains and policy alignment.

At kgreenpack we turn post‑consumer fibre into sturdy, elegantly moulded carriers that meet modern regulatory frameworks and elevate brand aesthetics. This expanded guide explains why a recycled‑pulp Cup Holder is more than a marketing flourish—it is a strategic compliance tool, a carbon‑reduction lever, and a tangible symbol of the circular economy in motion.

Malaysia’s 2025 single‑use‑plastic ban extends to food‑service accessories, nudging hawker stalls and drive‑throughs alike to adopt compostable drink carriers.

EU Packaging and Packaging Waste Regulation (PPWR 2024) sets a 90 % collection target for single‑use beverage packaging by 2029 and rewards fibre‑based designs that are easily recyclable at scale.

United States Extended Producer Responsibility (EPR) statutes in California, New York, and Oregon impose eco‑modulated fees that penalise difficult‑to‑recycle plastics but credit high post‑consumer‑content fibre.

Collectively, these measures shift both cost burden and reputation risk onto brands that remain reliant on virgin polymers. A recycled‑pulp Cup Holder helps operators sidestep impending levies while signalling proactive stewardship to regulators and consumers alike.

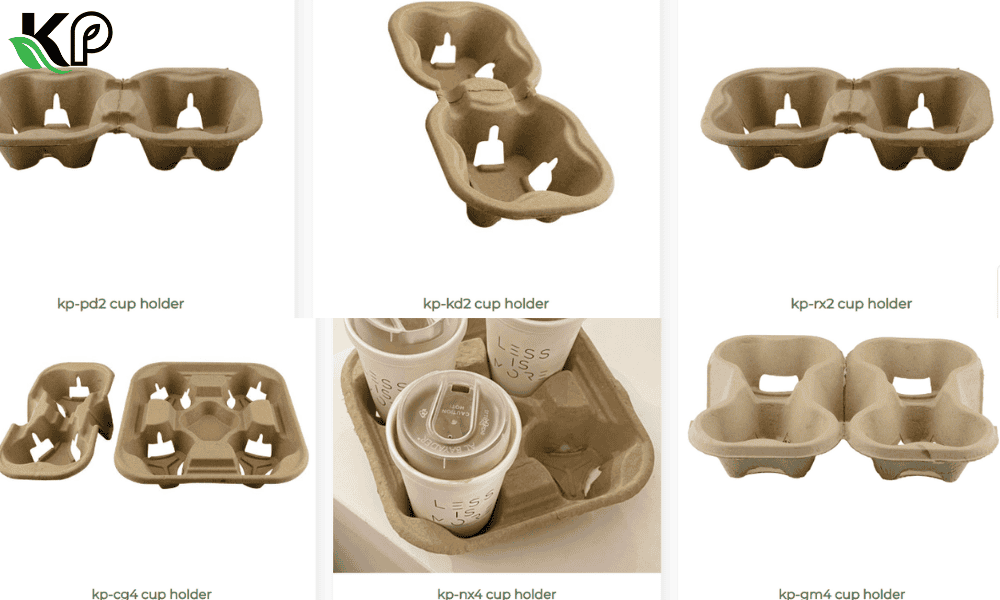

Global Hot Selling Cup Holder

Recycled‑pulp carriers begin life as office paper, cardboard boxes, and newsprint diverted from landfill. After mechanical shredding, the fibres form a watery slurry. Precision vacuum‑forming shapes that slurry into four‑cup, two‑cup, or single‑sleeve moulds; controlled oven‑drying creates a rigid matrix capable of supporting more than ten kilograms of vertical load.

Key performance features include:

Closed‑Loop Resin‑Free Structure – no polyethylene coatings, ensuring complete disintegration in industrial composters within 90 days.

High Thermal Insulation – micro‑air pockets in the fibre lattice keep 95 °C beverages comfortable to carry.

Moisture Resistance without PFAS – water‑based sizing agents protect fibres during the 30‑to‑60‑minute “last mile,” yet do not interfere with repulping.

Lightweight Strength – density‑optimised geometry withstands bumps and jolts inside delivery bags or ride‑share car boots.

For baristas, the tactile experience is equally important. The slightly textured rim of a kgreenpack carrier provides grip even when hands are damp with steam, reducing accidental drops at the service window.

| Attribute | Recycled‑pulp Cup Holder | EPS foam carrier | Rigid PET carrier |

|---|---|---|---|

| Renewable content | 95‑100 % post‑consumer fibre | 0 % | <10 % rPET |

| Compostability | 100 % (≤90 days industrial) | Non‑compostable | Non‑compostable |

| EPR / eco‑tax risk | Low | Very high | Moderate |

| PFAS / plasticiser use | None | Possible | Possible |

| Branding surface | Printable, debossable | Poor | Moderate |

| Average carbon footprint* | 40‑60 % lower than EPS | — | — |

A recycled‑pulp Cup Holder illustrates how a throw‑away item can travel full circle:

Collection – Post‑consumer cardboard is baled at grocery depots.

Reprocessing – Mills pulp the fibre using predominantly renewable electricity.

Carrier Production – kgreenpack blends reclaimed fibre with food‑safe, starch‑based binders; water is recirculated in a closed‑loop system that reduces consumption by 72 %.

Use Phase – Cafés distribute carriers; customers reuse them for second rounds, extending functional life.

End‑of‑Life – Carriers enter paper‑recycling streams, organic‑waste bins, or industrial composters, where they break down into biomass.

This loop satisfies emerging “material circularity indicators” (MCI) that large beverage chains must track in annual ESG disclosures.

Singapore: A leading coffee franchise migrated from plastic drink trays to kgreenpack pulp carriers, cutting packaging compliance fees 18 % and boosting customer perception of environmental responsibility by 22 % in third‑party surveys.

Northern Europe: A quick‑service burger giant adopted four‑cup carriers and shaved 30 seconds off average service time because baristas could preload the carrier without worrying about collapse or leaks, improving throughput and reducing drive‑through queue idling.

Seattle: An artisan roaster piloted embossed single‑cup holders for walk‑up traffic. Instagram posts featuring the embossed fibre aesthetic saw twice the engagement of plain cardboard sleeves, converting online clicks into store visits.

Recent Nielsen polling across eight markets shows that 68 % of Gen Z and Millennial consumers associate paper‑based takeaway accessories with higher product quality and brand trustworthiness. Three elements matter most:

Tactile Integrity – no soggy bottoms or warping.

Visual Cues of Sustainability – natural brown hue, visible fibre texture, minimalist ink use.

Re‑usability Potential – ability to repurpose the Cup Holder in the office or at home before disposal.

Meeting these expectations turns an ordinary carrier into a micro‑story of brand values.

Wholesale Cup Holder

Match Well Depth to Cup Size – 200‑250 ml drinks fit best in 55 mm wells; large iced beverages require 65 mm for stability.

Deboss Rather than Print – embossed logos eliminate inks, cut procurement costs, and comply with zero‑additive sourcing rules.

Optimise Nest Count – 50‑piece stacks keep pallets under 1.1 m, reducing freight emissions and warehouse space.

Integrate Accessory Slots – moulded indentations for paper straws or wooden stirrers add convenience without secondary packaging.

Plan for Multi‑Modal Delivery – carriers designed with reinforced corner ribs survive e‑bike vibrations better, reducing spillage claims.

Our ISO 14001 and ISO 9001 certified plant operates on 100 % renewable electricity. Real‑time moisture sensors ensure consistent carrier weight within ±2 g, guaranteeing uniform stack height—a boon for automated dispensers in high‑volume cafés. AI‑powered vision systems scan for edge roughness and incomplete wells, rejecting defects at a rate of 0.15 %, well below industry averages.

We offer:

Batch‑level recycled‑content certificates for EPR reporting.

Custom tooling with 10‑day lead times using 3‑D‑printed aluminium moulds.

On‑site compostability testing, verifying 90 % mass loss within 68 days at 58 °C.

Carbon‑footprint dashboards so clients can quantify Scope 3 reductions tied to carrier switching.

Even in jurisdictions lacking industrial composting, pulp carriers excel. If mixed with general paper streams, fibres can be repulped up to five additional cycles before degradation. Where waste‑to‑energy is prevalent, pulp’s high biogenic fraction ensures a lower net fossil‑carbon release than plastic. Importantly, a recycled‑pulp Cup Holder avoids microplastic generation in marine environments, aligning with the UNEP Global Plastics Treaty draft goals.

Stored below 75 % relative humidity and 25 °C, carriers maintain structural integrity for 18 months. Using a moisture‑barrier outer carton extends shelf life even in tropical settings.

No. Water‑based sizing keeps fibre bonds intact for at least two hours of typical transit time, maintaining rigidity and grip.

Absolutely. Our engineers create prototype moulds within 10 days, enabling pilot runs in under a month.

Carriers can enter mixed‑paper recycling or general landfill. Even in landfill, pulp’s rapid anaerobic breakdown and low additive content reduce methane potential compared with coated boards.

Material scientists are exploring hybrid approaches—combining recycled pulp with mycelium or seaweed fibres to boost barrier properties while preserving compostability. Meanwhile, digital watermarking embedded in the Cup Holder rim promises to automate sorting in next‑generation recycling facilities.

Regulators are watching closely: the EU Horizon Europe programme has earmarked grants for “intelligent fibre‑based packaging” that reports its own recycled content via QR code. Brands adopting these innovations early could secure expedited approvals and lower EPR fees.

Recycled Paper Pulp Products Cup Holder

As nations escalate their fight against single‑use plastics, cafés, quick‑service chains, and independent roasters face a decisive choice: adapt packaging strategies or absorb escalating costs and reputational risk. The recycled‑pulp Cup Holder answers this challenge with an elegant blend of practicality and principle. It converts waste into value, meets compostability targets without PFAS or bioplastics, and adds a tactile story of sustainability to every latte served.

Policy momentum is accelerating. Malaysia’s 2025 ban, the EU’s PPWR, and North American EPR statutes all converge on one conclusion—future‑proof packaging must fit seamlessly into both circular fibre loops and organic‑waste channels. By switching to pulp‑based carriers today, operators lock in lower material levies, simplified recycling logistics, and a compelling narrative for eco‑conscious consumers.

At kgreenpack, we view the Cup Holder not as a commodity but as a catalyst—proof that even the smallest accessories can harmonise profitability with planetary boundaries. Our recycled‑pulp lines empower partners to serve everything from cortados to large‑format bubble teas, confident they comply with tomorrow’s rules, today. Joining the pulp revolution means joining a broader cultural shift where every sip supports forests replanted, fibres reborn, and communities inspired to consume more thoughtfully.

In a world where a coffee’s worth is measured not just by its aroma but by its afterlife, choosing a recycled‑pulp Cup Holder is choosing the future.

Previous News

Sustainable Policy Integration: The Future of R...Next News

The Future of Sustainable Takeaway Packaging: S...

The KP-BN02 Cup Holder is an excellent choice ...

The KP-KD1 Cup Holder is designed to provide a ...

The KP-MD4 Cup Holder is designed to provide a ...